Concentric Cable plays a critical role in modern electrical distribution systems, offering a unique design that sets it apart from traditional single-core and multi-core cables. Unlike standard cables, concentric cables feature a central conductor surrounded by layers of insulation and a concentric neutral or return path, which enhances both safety and efficiency. This structural difference allows them to handle higher currents, reduce electromagnetic interference, and provide a more reliable power supply, making them ideal for urban power networks, industrial installations, and underground distribution systems.

In comparison, single-core cables, while simple and widely used, require careful handling to prevent voltage drops and often need additional protective measures. Multi-core cables, on the other hand, combine several conductors in one sheath but can face limitations in mechanical strength, heat dissipation, and installation flexibility. Concentric cables address these challenges with a design that balances durability, cost-effectiveness, and performance.

The benefits extend beyond technical specifications. Concentric cables can save installation space, reduce long-term maintenance costs, and improve overall system reliability. As power demands continue to grow, selecting the right cable type becomes crucial for both safety and operational efficiency.

Concentric Cable Benefits Over Single-Core and Multi-Core Cables You Should Know

In this guide, we will explain the key advantages of concentric cables over single-core and multi-core cables, supported by practical examples.

Concentric Cable – Understanding Cable Types

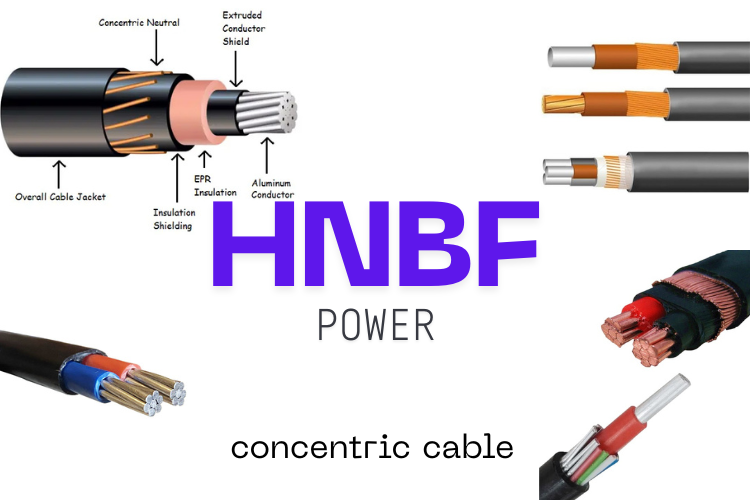

Concentric cable is a conductor design where a central core is surrounded by one or more layers of conductor strands arranged concentrically to form a neutral or return path. In practice, the core carries the phase (live) conductor while the surrounding concentric wires act as the neutral or sheath. Single-core cables have a single insulated conductor used for one circuit, and multi-core cables contain multiple insulated conductors bundled within a common sheath to serve several circuits or phases. The practical differences come down to construction, use case, and installation constraints.

Single-core cables are common where separate conductors are required for each phase and neutral, such as in switchgear or long transmission runs where heat dissipation and high voltage clearances matter. Multi-core cables are used to run several conductors together for example, three-phase plus earth in a single outers heath simplifying routing in control panels and short distribution runs. Concentric cable sits between these types: it integrates the neutral or return into the same radial structure but keeps the live conductor separate and centered.

Key technical points to note: concentric neutral construction reduces the need for a separate neutral conductor running alongside the phase conductor; concentric designs can use copper or aluminum depending on cost and conductivity needs; insulation thickness and conductor cross-section determine ampacity and voltage rating. Selecting between these types requires assessing electrical load, installation environment, mechanical stresses, and regulatory requirements.

Enhanced Safety Features

Concentric cable improves safety primarily by integrating the neutral or return path as a surrounding conductor, which changes fault behaviour and mechanical protection compared to single-core and multi-core options. With the neutral wrapped concentrically, the neutral is physically closer to the phase conductor along the cable length, which reduces loop area for fault and electromagnetic fields. A smaller loop area means reduced induced voltages in nearby metallic structures and lower potential for stray currents during transient events.

Mechanically, concentric conductors often provide a built-in return path without needing separate exposed neutral runs. This reduces points of connection and potential contact errors during installation. Fewer external connections translate to fewer opportunities for loose terminal connections, which are a common origin of overheating and arcing. On overhead or exposed runs, concentric sheaths can also serve as a radial protective layer that simplifies bonding and earthing practices.

From a fault management perspective, the concentric neutral supports more predictable clearing of short circuits. Protection coordination fuse or breaker sizing, relay settings benefits from the reduced reactance and controlled impedance of the concentric run compared to a physically separate neutral conductor. That predictability helps protection systems operate within designed time-current characteristics, limiting thermal and mechanical stress on equipment.

Installation safety is enhanced because concentrically neutralized cables reduce the number of loose conductors in trenches or ducts. Fewer individual conductors reduce the likelihood of accidental contact during handling. Overall, concentric construction lowers many common installation and operational hazards associated with separate neutral runs.

Improved Reliability and Durability

Concentric cable construction contributes to reliability through simplified assembly and reduced component interfaces. The integrated neutral reduces the number of separate conductors that must be terminated, lowering termination points where corrosion, loosening, or improper torque can cause failures. Each avoided joint is a reliability gain because joints are the most common single location for degradation over time.

Mechanically, a concentric layer provides radial support to the central conductor and helps distribute mechanical stresses under bending, pulling, or impact. This is particularly relevant during installation in ducts, conduits, or when cable must be pulled over long distances. The concentric layer can act as reinforcement, reducing the strain on the core conductor and its insulation. This translates to fewer insulation breaches and longer in-service life.

Thermally, concentric designs can offer more uniform heat distribution in certain configurations. With the neutral wrapped around the live conductor, local hot spots caused by uneven conductor grouping are less common. That consistency preserves insulation integrity and reduces aging rates. Material choices copper versus aluminum also influence durability: copper concentric conductors show superior long-term conductivity retention and corrosion resistance; aluminum offers weight and cost advantages but requires attention to oxidation and joint design.

Operationally, reduced electromagnetic interference, stable impedance, and predictable fault currents all make system behaviour more consistent, simplifying maintenance and diagnostics. Together, these characteristics mean concentric cable installations often exhibit fewer failures and require less corrective maintenance compared with equivalent systems using separate neutral runs or complex multi-core bundles.

Efficient Power Distribution

Concentric cable supports efficient distribution by combining the phase and neutral paths in a single radial geometry, which reduces conductor length and complexity for neutral return paths. This layout shortens the overall conductor inventory required for a distribution run and simplifies route planning. Fewer separate runs mean lower material transport and installation labour per circuit.

Electrical efficiency benefits from the concentric geometry because of reduced loop impedance. When the neutral is close to the phase conductor, the mutual coupling lowers loop reactance and reduces voltage drop under load for a given conductor size. Lower voltage drop improves delivered power quality over distance and can reduce the need for higher conductor cross-sections to meet regulatory voltage drop limits.

Concentric cables also streamline phase-to-neutral balancing in low-voltage distribution. With predictable impedances and common environmental exposure, balancing loads across multiple installed concentric runs is easier to model and verify. This predictability supports accurate load flow calculations and makes it simpler to size protection and conductors without large conservative safety margins.

In practical terms, concentric cables can reduce installation time and material waste. For municipal or commercial distribution street lighting, small feeders to buildings, or lateral service connections the concentric approach reduces trench width or conduit fill, allowing denser cable placement and lower civil costs. Efficiency here is both electrical (reduced losses, less voltage drop) and logistical (simpler installations, fewer components).

Cost-Effectiveness

Cost-effectiveness of concentric cable arises from multiple factors: material, installation labour, and lifecycle maintenance. While concentric designs may use slightly more conductor material per meter because they include the concentric neutral layer, they eliminate the need for separate neutral runs and many additional terminations. Fewer terminations and shorter total conductor lengths reduce labour costs, which can dominate total project expenditure in complex installations.

Economies appear in trenching and conduit sizing as well. A single concentric run often requires smaller ducts or narrower trenches compared to multiple single-core cables laid in parallel. That reduces excavation volume, backfill materials, and civil works time. For urban projects where civil work costs are high, the reduced footprint translates to real savings.

On maintenance costs, concentric cables tend to present fewer failure points due to fewer joints and a combined structure that is easier to protect and inspect. Lower failure rates mean fewer outage events and less emergency repair labour. That long-term reduction in corrective maintenance can offset any initial premium on cable cost.

When selecting materials, aluminum concentric cables lower upfront conductor cost and reduce weight for handling savings. Copper options cost more but provide lower resistive losses and often extend service life. The cost decision should account for total cost of ownership: initial cable price plus predicted losses, maintenance frequency, and replacement cycles. For many distribution applications, concentric cables strike a favourable balance between initial cost and operational economy.

Space-Saving Design

One of the practical benefits of concentric cable is space efficiency. Because the neutral is wrapped concentrically rather than run as an additional separate conductor, the overall cross-sectional footprint for a given circuit can be reduced compared with laying multiple single-core cables or a bulky multi-core assembly. This space saving matters in ducts, conduits, cable trays, and underground pits where capacity is constrained.

A smaller physical footprint reduces conduit fill percentage and allows additional utilities to share the same route. In dense urban corridors, this can avoid costly additional ducts or diversions. For retrofit projects, concentric cables can often fit into pre-existing raceways without major enlargement, cutting upgrade costs and minimizing civil disruption.

Space savings also translate to lower installation complexity. In cable trays or ladder systems, fewer separate cables mean easier routing, bundling, and labeling. It reduces the time technicians spend arranging and securing multiple conductors, which speeds installation and reduces error potential.

Finally, the compact nature assists in vertical installations within buildings or towers where shaft space is limited. Concentric runs can be stacked with minimal separation, and their predictable geometry simplifies fire-stopping and mechanical fixing design. In sum, when installation space is at a premium, concentric cable offers clear logistical advantages that influence both capital and operational planning.

Reduced Electromagnetic Interference

Concentric cable geometry inherently reduces electromagnetic interference because the neutral conductor is closely wrapped around the phase conductor. This proximity reduces electromagnetic loop area and therefore lowers the magnetic field that radiates from the cable assembly. A smaller radiated field reduces induced voltages in nearby metallic structures, control cables, and sensitive electronics.

Practically, this means concentric cables are less likely to cause cross-talk into signal or communication lines when routed in parallel or in shared ducts. For installations where power and control or data cables run adjacent, reduced interference simplifies shielding requirements and reduces the need for additional segregation measures.

Lower external fields also benefit equipment immunity. Sensitive metering, control relays, and telemetry systems operate more reliably when nearby power conductors have minimal stray fields. In industrial settings where electromagnetic compatibility standards must be met, concentric layouts can ease compliance and reduce the cost of extra filtering or screening.

Additionally, reduced field emission diminishes eddy current and induced heating in nearby metallic structures. That lowers ancillary thermal loads on support structures and reduces the potential for galvanic corrosion driven by stray currents. For installations where EMI management is important, including substations and data centre feeders, concentric cable offers an effective passive solution.

Versatility in Applications

Concentric cable is versatile across many distribution contexts due to its combined electrical and mechanical characteristics. It is commonly applied in service connection runs, street lighting feeders, short to medium length distribution feeders, and certain industrial lateral circuits. The design is adaptable for overhead, underground, and ducted installations depending on insulation and armouring selections.

The concentric design works with both copper and aluminum conductors, allowing specification to match project constraints: copper where space and conductivity are priorities; aluminum where weight and cost are limiting factors. Various insulation systems (PVC, XLPE, EPR) can be used with concentric conductors to meet voltage class and environmental needs, from low-voltage building supplies to medium-voltage distribution feeders.

Installation flexibility extends to variants with one or more concentric layers, enabling neutral sizing to match load requirements or to provide additional mechanical strength. Armoured concentric cables add mechanical protection for direct burial or exposed routing while maintaining the electrical benefits of the geometry.

This versatility makes concentric cable a pragmatic choice where mixed requirements exist: constrained space, predictable load profiles, and a need for straightforward earthing or bonding. For project planners, the ability to tailor conductor material, insulation, and armouring in a concentric format simplifies standardization across multiple application types.

Urban Power Distribution

In urban distribution contexts, concentric cable offers practical advantages tied to compact routing, reduced civil works, and simpler neutral management. Urban feeders tend to be short to medium length with frequent lateral connections to buildings and street furniture; the concentric design fits this pattern by minimizing separate neutral runs and allowing compact installation in existing ducts and chambers.

City infrastructure often has limited duct and pit capacity. Concentric runs permit denser population of utilities within the existing right-of-way, avoiding expensive excavation to expand capacity. The integrated neutral also simplifies jointing and termination at distribution pillars or service boxes where space and accessibility are constrained.

From a maintenance perspective, fewer external conductors and predictable impedance behaviour make fault location and isolation faster. In crowded urban networks, reducing outage duration is important to minimise commercial and residential disruption. Concentric cable installations can reduce intervention complexity because bonding and earthing are integral to the cable design, making routine inspection and testing more straightforward.

Municipal lighting, small commercial feeders, and residential service connections are common urban use cases for concentric cables. When planning upgrades or densification projects, engineers frequently choose concentric formats to balance space constraints, installation cost, and operational reliability.

Conclusion

Concentric cable provides a combination of electrical and practical benefits that set it apart from single-core and multi-core alternatives. Its integrated neutral reduces installation complexity, lowers electromagnetic emissions, and supports more predictable fault and thermal behaviour.

Mechanically, concentric constructions improve handling and reduce the number of termination points, which enhances reliability over time. Space savings and installation efficiency deliver cost advantages in constrained environments such as urban ducts and building shafts.

Selection decisions should weigh material choices, insulation systems, and local standards, but for many distribution and service applications, concentric cable is a pragmatic, performance-oriented option.