Power cable maintenance is a critical aspect of ensuring safe, reliable, and long-lasting power distribution across industrial, commercial, and utility networks. Proper maintenance not only prevents unexpected outages but also extends the operational life of cables, reduces repair costs, and improves overall grid efficiency.

In modern power systems, cables whether overhead conductors like AAC, AAAC, ACSR, or low-voltage XLPE and PVC power cables are subjected to various mechanical, thermal, and environmental stresses. Factors such as heavy current loads, temperature fluctuations, moisture ingress, UV exposure, and physical wear can accelerate cable degradation if not properly monitored and addressed.

Regular maintenance helps identify early signs of damage, including insulation wear, corrosion, overheating, and joint failures, which are common causes of power interruptions in utility networks. For electrical engineers, contractors, and facility managers, implementing a structured cable maintenance program ensures operational safety and compliance with industry standards.

From inspection routines and load management to environmental protection and timely repairs, a comprehensive approach to cable care is essential for maintaining uninterrupted power flow.

Power Cable Maintenance: Practices for Safe and Long-Lasting Power Distribution.

In this guide, you will learn the key factors that affect power cable lifespan and the importance of regular maintenance.We will also cover practical techniques, inspection methods, and best practices to ensure safe and reliable power distribution.

1. Introduction to Power Cable Maintenance

Power cable maintenance ensures continuous, safe, and stable electricity distribution across industrial, commercial, and utility networks. Whether it is LV power cables, overhead conductors, or ABC cables, regular maintenance helps reduce outages, prevent equipment damage, and extend the cable’s service life. Utilities, contractors, and infrastructure developers consider maintenance an essential part of long-term grid reliability.

In regions with growing energy demand, power distribution networks face heavier loads. This makes preventive maintenance more important than ever. A structured maintenance plan helps identify problems before they cause failures.

2. Key Factors That Accelerate Power Cable Degradation

Cables degrade due to mechanical, thermal, chemical, and environmental factors. Understanding these factors helps maintenance teams plan inspections and prioritize high-risk zones.

2.1 Mechanical Stress

Cables in overhead lines and underground ducts experience mechanical stress from vibration, tension, bending, or improper handling during installation. Over time, this stress can weaken conductors, joints, and insulation.

2.2 Thermal Aging

Continuous high current loads increase temperature, leading to insulation hardening or shrinkage, especially in PVC and XLPE power cables. Temperature cycles cause expansion and contraction, which accelerates insulation deterioration.

2.3 Moisture and Water Ingress

If underground or exposed cables are not adequately sealed, moisture can enter through joints or damaged insulation. Water ingress reduces insulation resistance and increases the risk of short circuits.

2.4 Environmental Contaminants

Pollution, chemical exposure, salt spray (in coastal areas), and UV radiation can degrade overhead cables, especially AAC and ACSR conductors. Regular inspection helps detect early signs of corrosion or conductor fatigue.

3. The Importance of Regular Power Cable Inspections

Inspections allow utilities and engineers to detect degradation early. Scheduled inspections reduce unplanned downtime and extend cable lifespan.

3.1 Visual and Physical Inspections

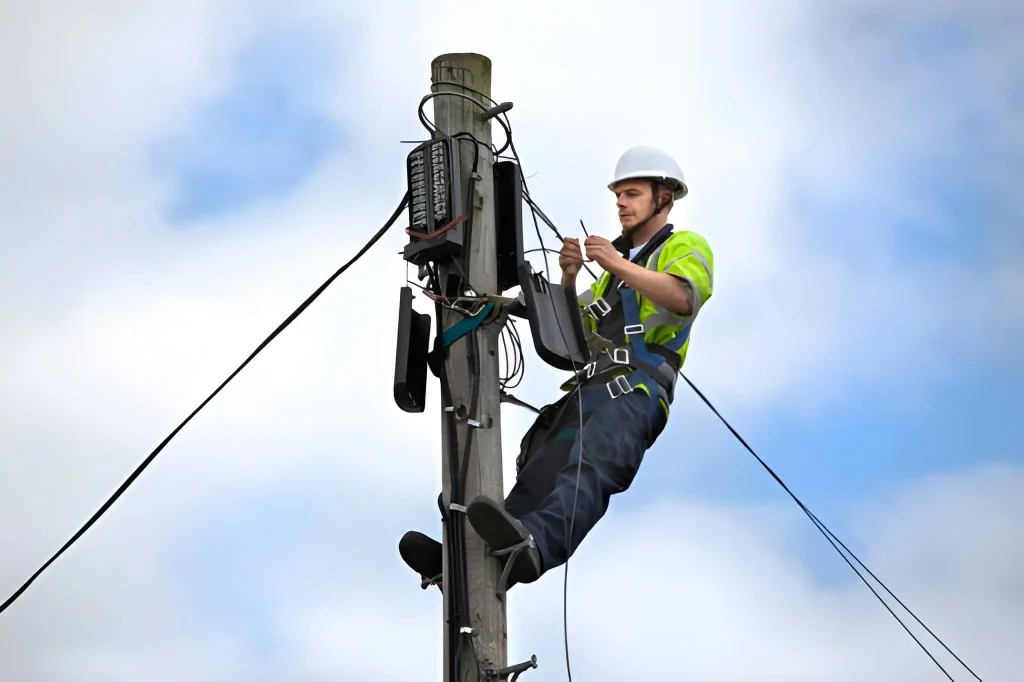

Teams should regularly check for cracks, discoloration, corrosion, insulation swelling, joint damage, and loose terminations. Overhead lines require additional checks for sagging, bird damage, or mechanical wear.

3.2 Electrical Testing

Insulation resistance tests, continuity checks, partial discharge measurements, and load tests help identify internal defects that are not visible. Many utilities perform annual or bi-annual testing on critical feeders.

3.3 Condition Monitoring

Modern maintenance programs include continuous monitoring using sensors or handheld tools. Tracking temperature, load profile, and insulation condition helps predict failures. Utilities are increasingly adopting predictive maintenance, especially for long LV feeders and high-risk distribution lines.

4. Proper Cable Installation and Routing

Correct installation significantly reduces long-term maintenance requirements. Many failures occur due to poor installation practices rather than material issues.

4.1 Correct Cable Bending Radius

Every cable type whether LV XLPE, ABC, AAC, or ACSR has a minimum bending radius. Exceeding this radius weakens insulation and conductor strands. Utility crews must follow standard bending guidelines during installation.

4.2 Routing and Separation

Cables should be routed to avoid excessive heat, magnetic interference, or direct contact with other hardware. Underground cables must have adequate spacing and follow trenching standards to prevent overheating.

4.3 Jointing and Termination Quality

Improper joints are one of the leading causes of failures. High-quality joints and terminations reduce partial discharge, limit resistance at connection points, and support long-term reliability. Using certified accessories and trained technicians ensures consistency.

4.4 Mechanical Protection

Where cables cross roads, bridges, or industrial zones, mechanical protection such as conduits, ducts, or protective plates reduces risks from construction and movement.

5. Temperature Monitoring in Power Cable Maintenance

Temperature has a direct impact on cable performance and lifespan. Monitoring ensures that cables operate within safe thermal limits.

5.1 Load-Induced Heating

When the cable carries more current than its rated capacity, it heats up. Excessive heating accelerates insulation aging and can lead to cable failure.

5.2 Ambient Temperature Effects

High-temperature climates increase conductor temperature. For overhead lines, sunlight exposure raises conductor sag. Utilities must account for seasonal temperature variations.

5.3 Hot Spot Detection

Infrared cameras or thermal sensors help detect overheating joints, terminations, or specific cable sections. Hot spots indicate potential faults that require immediate attention.

5.4 Monitoring Systems

Some utilities use real-time thermal monitoring systems for critical networks such as substations or industrial power feeds. These systems provide alerts when temperatures exceed allowable limits.

6. Environmental Protection for Long-Lasting Cable Performance

Environmental exposure significantly influences cable lifespan. Proper protection reduces degradation and improves reliability.

6.1 UV and Weather Protection

Overhead cables are exposed to sunlight, rain, wind, and pollution. UV-resistant insulation or shielding reduces aging and mechanical wear.

6.2 Corrosion Control

In coastal, industrial, or polluted environments, corrosion can affect steel cores of ACSR conductors or metallic components. Anti-corrosion coatings and proper grounding can reduce damage.

6.3 Moisture Control for Underground Cables

Underground cables require moisture barriers, proper sealing at joints, and adequate drainage. Water-logged trenches significantly increase failure risk.

6.4 Animal Protection

Rodents, birds, and insects can damage cable insulation or overhead conductor accessories. Barriers and protective covers help minimize such risks.

7. Load Management to Prevent Overloads and Failures

Load management is critical in preventing cable overheating and long-term insulation damage.

7.1 Load Balancing

Unequal load distribution increases stress on specific phases. Balanced load distribution reduces heating and prevents voltage drops.

7.2 Avoiding Overloads

Cables must operate below their rated current-carrying capacity. Overloads cause insulation degradation, sagging in overhead lines, and accelerated aging.

7.3 Demand Growth Planning

With increasing energy consumption, utilities must periodically reassess cable capacities. If loads increase, replacing or upgrading conductors (AAC → AAAC → ACSR) may be necessary.

7.4 Short-Circuit Management

Short-duration overloads during faults can heat cables rapidly. Proper protection systems ensure that faults are cleared quickly to limit damage.

8. Timely Repairs and Replacements

Delaying repairs increases the risk of failure and outages. Maintenance teams must identify when a cable should be repaired or replaced.

8.1 Indicators for Repair

Minor insulation cracks, loose connections, or corroded fittings can be repaired if detected early. Repairs reduce further degradation.

8.2 Indicators for Replacement

Cables require replacement when:

- Insulation resistance is below safe limits

- Repeated overheating occurs

- Conductor strands show corrosion or fatigue

- The cable has exceeded its design lifespan

8.3 Replacement Planning

For utility networks, replacing overhead conductors or LV feeders often depends on load demand, environmental conditions, and system reliability goals. Planning ahead minimizes downtime.

9. Best Practices for Utility-Scale Power Cable Maintenance

Utility networks require structured maintenance routines that ensure long-term grid stability.

9.1 Preventive Maintenance

Scheduled inspections, thermographic scanning, and regular electrical testing identify early-stage issues. Preventive measures reduce unplanned failures.

9.2 Predictive Maintenance

Using sensors and monitoring tools helps utilities predict failures before they occur. Predictive maintenance is increasingly adopted in growing urban networks.

9.3 Documentation and Data Tracking

Maintenance logs, test reports, and asset records help engineers track the condition of cables over time and plan replacements effectively.

9.4 Training and Safety

Maintenance crews must follow safety protocols, use certified tools, and adhere to local standards. Proper training ensures consistent quality and reduces on-site risks.

10. Where to Source Reliable Power Cables

Using high-quality conductors and cables reduces long-term maintenance needs. Utilities and contractors prefer suppliers that offer consistent quality, testing reports, and international-standard compliance.

HNBF Power manufactures overhead conductors (AAC, AAAC, ACSR), ABC cables, LV power cables, and related products used in distribution networks globally. The company follows standard manufacturing processes, offers quality assurance testing, and supports international infrastructure projects.

Reliable cables reduce failure risk, improve lifespan, and support long-term maintenance plans. For utility-scale projects or distribution networks, sourcing from manufacturers with proven quality control ensures stable performance.

FAQS

1. What is power cable maintenance and why is it important?

Power cable maintenance involves regular inspection, testing, and repair of electrical cables to ensure safe and reliable power distribution. It helps prevent failures, extends cable life, and reduces downtime.

2. How often should power cables be inspected?

Inspection frequency depends on the cable type and operating environment. For high-voltage or critical distribution lines, annual inspections are common, while low-voltage and industrial cables may require semi-annual checks.

3. What are the common causes of cable degradation?

Mechanical stress, thermal aging, moisture ingress, UV exposure, chemical contamination, and overloading are the main factors that degrade power cables over time.

4. How can I detect early signs of cable damage?

Visual inspection for cracks, discoloration, or corrosion, combined with electrical tests like insulation resistance and thermographic scans, helps detect early issues before failure occurs.

5. What preventive measures can reduce cable maintenance needs?

Proper installation, correct bending radius, environmental protection, load management, and regular monitoring help prevent premature cable failure.

6. Can temperature monitoring improve power cable reliability?

Yes, monitoring conductor and ambient temperature helps identify overheating spots, preventing insulation damage and extending cable lifespan.

7. How should underground cables be maintained?

Ensure proper sealing at joints, moisture barriers, adequate drainage, and periodic testing to detect water ingress and insulation deterioration.

8. When should a cable be repaired versus replaced?

Minor insulation cracks or loose connections can be repaired, but cables with severe insulation degradation, corrosion, or aging beyond design life should be replaced.

9. What role does load management play in cable maintenance?

Balanced loads and avoiding overloads reduce heating and mechanical stress on cables, preventing insulation degradation and prolonging operational life.

10. Where can I source high-quality power cables for reliable maintenance?

Manufacturers like HNBF Power provide overhead conductors, ABC cables, and LV power cables with quality assurance and compliance with international standards, reducing long-term maintenance issues.

Conclusion

Power cable maintenance is essential for safe and long-lasting power distribution. By understanding degradation factors, conducting regular inspections, managing loads, and performing timely repairs, utilities and contractors can significantly extend cable lifespan. Modern monitoring tools and structured preventive maintenance improve reliability and reduce outages.

Selecting the right cable from a reliable manufacturer also makes long-term maintenance easier. High-quality conductors and power cables perform better under mechanical, thermal, and environmental stress, supporting stable and efficient distribution networks.